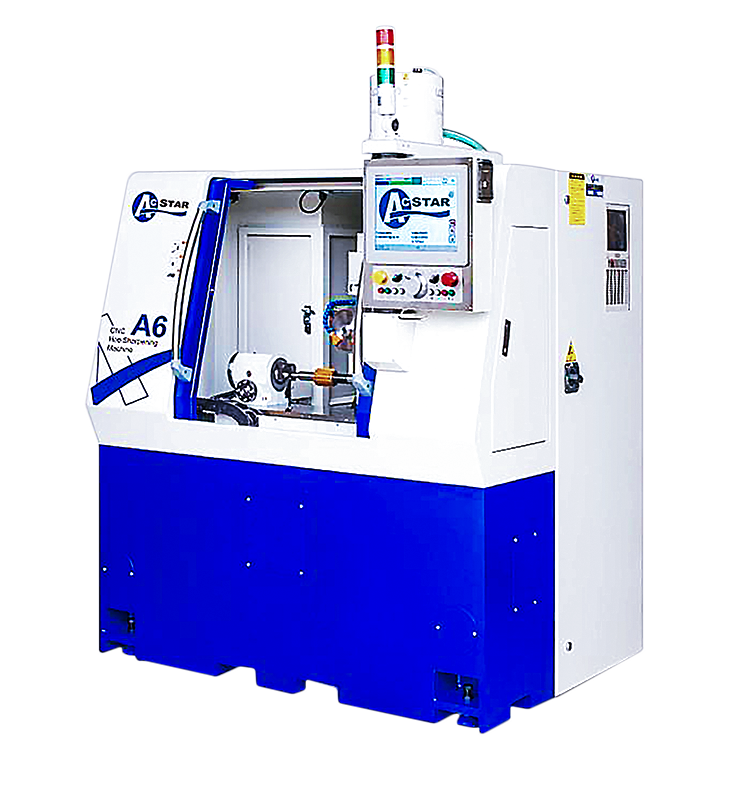

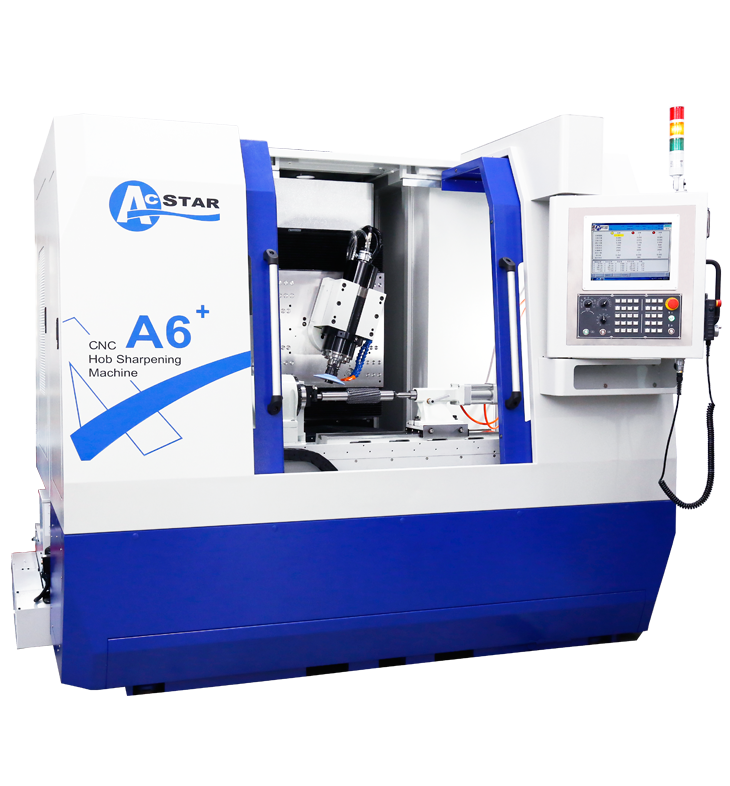

The A6 / A6+ CNC Hob Sharpening Machines from ACSTAR are developed with ACSTAR’s extensive experience in cutting tool machining equipment in combination with the latest technology. Featuring advanced computer control, the series of machine are high precision, versatile grinding machines with 5 axes control and 4 axes simultaneous control. These machines are applicable for sharpening hobs with straight and spiral flutes. In addition, upon customer’s requirement, these machines are available to design with an additional complicated part grinding function for sharpening the cutting edge of the slotting hob. The models A6(op) /A6+ employ HSK interchangeable grinding wheel shank that helps to reduce wheel change time during machining, resulting in a higher production efficiency and increase of customer’s product development competition capabilities. As such, ACSTAR A6 / A6+ series is your best choice in upgrading production competitiveness and product development.

| Model | A6+ |

|---|---|

| Gash Lead Range | |

| Min. / Max. workpiece diameter | 20 mm / 250 mm |

| Max. length | 300 mm |

| Max. grinding depth | 40 mm |

| Flute range | 1-99 |

| Lead angle range | ± 30° |

| Gash lead range |

1000-∞ mm (450 ∞ optional 選配) |

| Mechanical Specifications | |

| Min. / Max. distance between centers | 80 / 600 mm |

| Max. axial slide travel (Z axis) | 715 mm |

| Max. weight (workpiece with carrier) | 80 kg |

| Micro-Adjustment Tailstock | ± 60um (optional 選配) |

| Grinding Wheel Specifications | |

|

Min. abrasive grinding wheel root diameter / Max. grinding wheel diameter |

30 / 200 mm |

| Max. grinding wheel thickness | 25 mm |

| Max. rpm of grinding spindle | 10000 rpm |

| Drive power of grinding spindle | 18 KW |

| Electric System | |

| Voltage | 3Ø220V |

| Current Requirement | 75A |

| Ambient Temperature | 10˚C-40˚C |

| Max. Load of Machine | 30 KVA |

| Cnc Controller | |

| SYNTEC | |

| Cnc Controller | |

| Space Requirement (LxWxH) | 3500 x 2200 x 2100 mm |

| Weight of Basic Machine | 6200 kg |

STANDARD EQUIPEMT :

The specifications and design characteristics shown in this catalog are subject to change without prior notice.

Copyright © ACSTAR PRECISION MACHINERY CO., LTD.